Mahler is your full-service comprehensive manufacturing partner

Mahler has built a reputation over 40 years of reliability by producing the highest quality machined components delivered on-time, while maintaining competitive pricing.

Any Material

Metals, plastics, various exotics and in all formats including plate, bar stock or castings

Any Quantity

From rapid prototyping to production volumes of 5,000+ units / month

Any Part

19 Diverse CNC machines to manufacture virtually any component achieving complex geometries and tight tolerancing

Mahler has built a reputation over 40 years of reliability by producing the highest quality machined components delivered on-time, while maintaining competitive pricing.

Mahler is your full-service comprehensive manufacturing partner

Any Material

Metals, plastics, various exotics and in all formats including plate, bar stock or castings

Any Quantity

From rapid prototyping to production volumes of 5,000+ units / month

Any Part

19 Diverse CNC machines to manufacture virtually any component achieving complex geometries and tight tolerancing

In House Capabilities

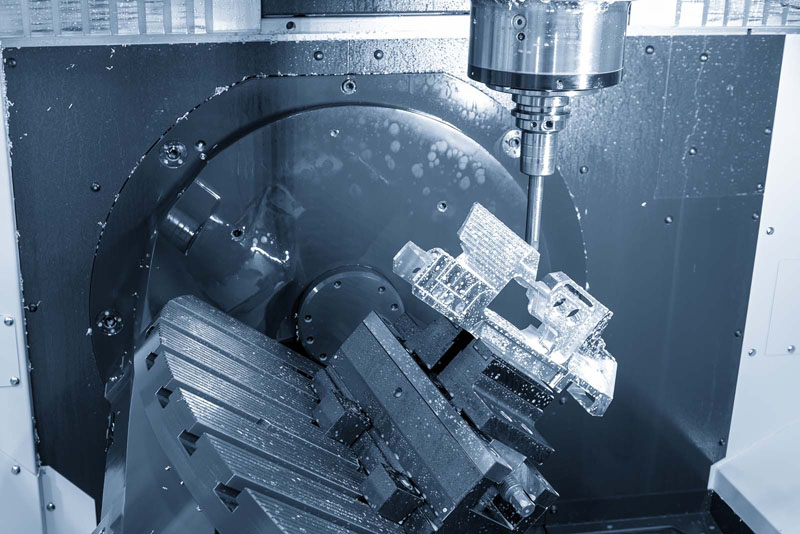

Mill/Turn 7 Axis Machining

3, 4, 5-Axis Milling

Horizontal Milling

Turning

Rapid Prototyping

Volume Production

Quality Management System

Design For Manufacturability

Inventory Management

CMM Inspection

Light Assembly

Sandblasting & Glass Beading

Trusted Supplier Network

Grinding

Heat Treating

Anodizing / Plating

Powder Coating

Fabrication / Waterjet Cutting

Testing

All Parts Receive In House Final Quality Control Inspection & Documentation

Core Capabilities

Our 19 CNCs provide comprehensive in-house capabilities to meet any machining need.

3, 4, 5-Axis Vertical CNC Milling

Vertical 3, 4, & 5-axis CNC milling capabilities for parts up to 84” in length

Horizontal CNC Milling

Horizontal machining utilizing tombstones and pallet changers for cost effective high volume production of complex parts

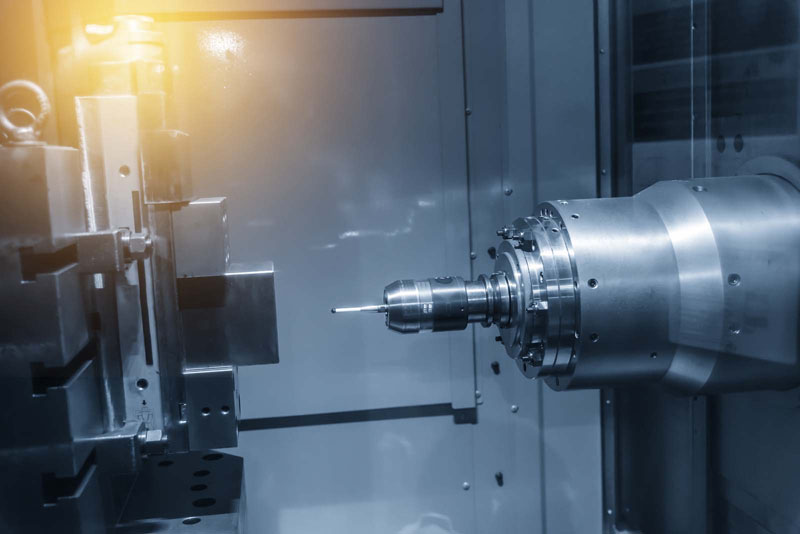

Mill/Turn 7 Axis CNC Machining

Mill-turns combine multiple operations for done in one machining of complex parts maximizing repeatability & quality

CNC Turning

Turning of 1/8” bar stock up to 23” diameter plate with 4 axis turning, live tooling, barfeed automation and sub-spindle capabilities

Rapid Prototyping

With stock inventory and dynamic machine capacity, we can turn drawings into prototypes rapidly with a path to volume production

Volume Production

Eliminate the risk of quality issues as we ramp from single part production to volume production in the thousands with a proven process

Design for Manufacturability

Leverage 40 years of machining history and experience to augment part design for manufacturability. Fit, Form, Function.

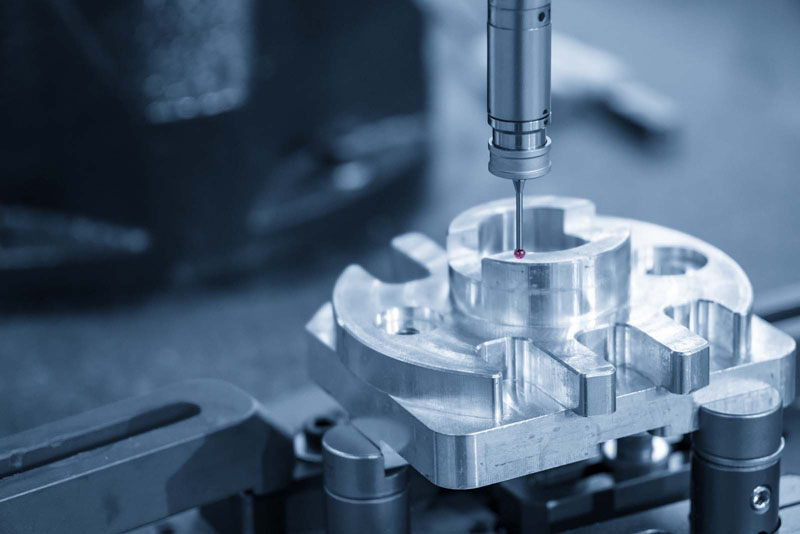

CMM Inspection

CMM inspection and coordinate system reports to guarantee dimensional accuracy

Quality Management System

Proven QMS system that has been in place for decades and ISO 9001:2015 certified.

Inventory Management

Kanban inventory system for our customers guarantees on-time delivery, secures volume pricing and helps reduce customer inventory levels

Assembly

Basic assembly for select parts as required for our clients

In-House Parts Finishing

In-house sandblasting, glass beading as well as vibratory polishing

Broader Capabilities

Access best-in-class part finishing and fabrication platforms through our vetted outsourcing partners.

Finishing

Anodizing, plating, black oxide, heat treat, powder coating, and laser engraving

Grinding

Long tenured relationship and priority service with top grinding shops in British Columbia for parts as required

Fabrication

Bending, forming, and welding

Waterjet Cutting

High volume profiling and sheet metal work

Testing

NDE/NDT including but not limited to ground penetrating, magnetic testing, optical emission, penetrant testing, positive material identification, radiographic and ultrasonic testing.