Precision CNC machining is the core of Mahler and has been for 40 years. With our fleet of 19 CNC machines run by our experienced and tenured staff we can meet most any machining need from prototype work to large volume production. Utilizing state of the art Mazak equipment we are able to achieve complex geometries, maintain exacting tolerancing and dimensional accuracy requirements, as well as provide for efficient high-volume production. The diversity of our equipment can accommodate intricate small parts such as those used in medical devices all the way to large housings up to 84” in length.

CNC Turning

Seven Mazak CNC lathes ranging in size capable of turning parts up to 22.8” in diameter. Turning centers equipped with live tooling, y-axis travel and sub-spindles for done in one machining of even complex parts typically requiring multiple operations supporting efficient production, better quality and greater repeatability regardless of part complexity. Efficient high-volume production supported by various automation strategies including bar feeders, parts catchers and workpiece conveyors.

| Number of Work Centers | 7 CNCs |

| Max Travel | X: 13.38” Y: 6.00” Z: 42.12” |

| Max Swing | 33.26” |

| Max Machining Length | 40.35” |

| Max Machining Diameter | 22.84” |

| Max Bar Capacity | 4.59” spindle & 3.00” bar feed |

| Chuck Size | 8” to 15” |

| Max RPM | 6,000 Turning & 6,000 Milling |

CNC Vertical Milling

Seven vertical CNC mills provide wide capabilities including highspeed milling, pallet changers for high volume production, high rigidity machines for tight tolerance work, and rotary 4th axes. All verticals equipped with in machine tool and part probing for maximum accuracy and repeatability and through spindle coolant for improved surface finishes and faster cycle times.

Large part machining capabilities up to 84” x 40” and 3,000 lbs.

| Number of Work Centers | 7 CNCs |

| Max Travel | X: 84.00” Y: 40.00” Z: 30.00” |

| Max Table Load | 3,000 lbs |

| Max RPM | 15,000 |

CNC Horizontal Milling

Two Mazak horizontal CNC mills equipped with pallet changers and four-sided tombstones support high levels of automation and lights out production capabilities. All horizontals equipped with in machine tool and part probing for maximum accuracy and repeatability and through spindle coolant for improved surface finishes and faster cycle times.

| Number of Work Centers | 2 CNCs |

| Max Travel | X: 27.95” Y: 24.02” Z: 25.98” |

| Max Table Load | 1,100 lbs |

| Max RPM | 12,000 |

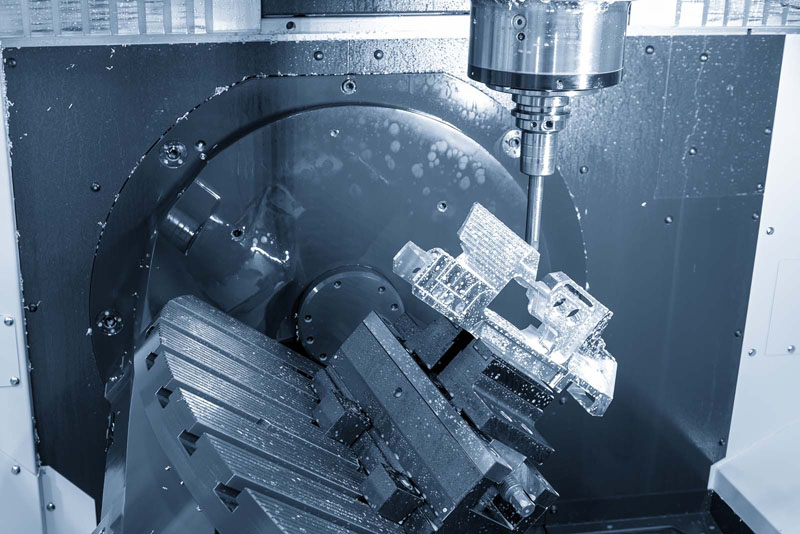

5-Axis CNC Machining

One Mazak 5 Axis machine for simultaneous 5-Axis machining to achieve complex geometries with unique curvatures as well as positional 5-axis machining reducing setup times and combining multiple operations into a single operation. CAD/CAM software utilized for offline programing of complex geometries.

| Number of Work Centers | 1 CNC |

| Max Travel | X: 19.88” Y: 19.88” Z: 20.07” B: 220° C: 360° |

| Max Table Load | 440 lbs |

| Max RPM | 12,000 RPM |

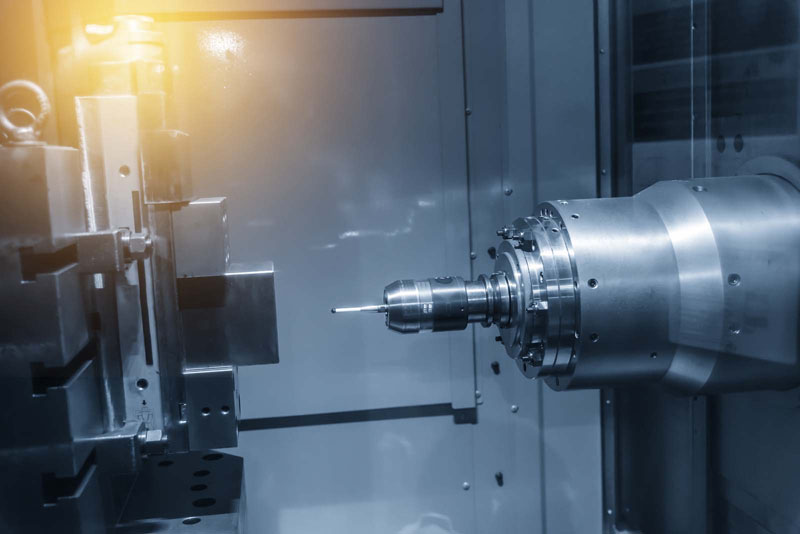

7-Axis Mill-Turn CNC Machining

Two Mazak Integrex mill-turns combine milling and turning into one 7-axis work center capable of done in one machining offering maximum repeatability and accuracy. Capable of machining complex geometries with high precision typically requiring multiple operations. Sub spindle availability to support part transfers where secondary operations are required on the rear face of a part.

| Number of Work Centers | 2 CNCs |

| Max Travel | X: 24.80” Y: 9.84” Z: 62.41” B: 240° C: 360° |

| Max Swing | 30.00” |

| Max Machining Length | 60.00” |

| Max Machining Diameter | 30.00” |

| Chuck Size | 12.00” |

| Max RPM | 4,000 Turning & 12,000 Milling |

Manual Machining

In addition to our CNC equipment we have a full manual machine shop for secondary operations and prototype work. Our manual machine shop includes three lathes, a vertical mill, a radial arm drill, several drill presses, grinders, and an automatic hone.